Vienna is one of Europe’s most beautiful capitals. Smaller in size than Paris but playing in a similar league in terms of architecture, it is quite possibly one of the chicest metropolitan destinations east of the Rhine. Similarly chic is Hemdenmacher Venturini (“Shirtmaker Venturini” in German), which is perched between other small shops in Spiegelgasse, an alley off the elegant shopping street Graben, in the centre of the city.

The Austrian capital is also one of relatively few remaining bastions of craft in central Europe, and within less than five minutes of Venturini you will find Vienna’s most famous tailor and gentleman’s outfitter, Knize, in his premises designed by Adolf Loos – where Marlene Dietrich had her tailcoats made. In an alley parallel to Spiegelgasse resides the bespoke shoemaker Scheer who made boots and shoes for Emperor Franz Joseph and his wife the Empress Elisabeth, and just a little further off is the prestigious cloth merchant Jungmann & Neffe. The owners of said merchant are in fact related to Nicolas Venturini himself, who, when I call in, is busy serving customers behind the counter of his tiny shop.

The astute among you will have clocked that ‘Venturini’ is not a typical Austrian name, and when Nicolas has a quick break between clients, he explains how his Italian family, who hail originally from Trieste, came to make their home Vienna. “My father went to a strict Catholic boarding school in Kärnten,” he says. “He came to Vienna in the late 1950s and started selling shirts made by a friend to finance his studies, but soon he realised that said shirts lacked the quality that he really wanted. So, he changed tack and had the shirts made in Vienna by a supplier, first ready-to-wear, then he started selling bespoke shirts in a small shop in the 4th district. In 1959 he managed to buy Hemden Herzog, which is our present location. When I took on the business in 2009 I changed the name to Venturini to honour my father.”

As we chat, a young man enters the shop with an appointment for a fitting. He is greeted with typical Viennese courtesy by two sales assistants and then led to the back of the shop. The fitting waits on a hanger. It’s made of an off-white cotton fabric woven especially for this purpose. The young man disappears for a moment in the changing booth. “My father performed a toile-fitting only on difficult figures, maybe for one out of 15 customers,” Nicolas continues. “I think it is better to make a toile-fitting for every new customer. My father was convinced that I would ruin our company in doing this. We sell about 1,800 gift vouchers for shirts each year – so, somebody gets this voucher from his aunt, he is happy to come to our shop, be measured and try a toile fitting. Sometimes, at that point, we will then make his first shirt and he will never come back to collect it. In this respect my father was right. But if you make bespoke clothes there is more to it than the profit alone. We want to do things well.”

The customer reemerges with a grin – evidently pleased with how his toile fits – and I wait in the sidelines while Nicolas concentrates on the fitting. In a hushed voice he walks through the trial shirt, beginning with the collar. A sales assistant notes the alterations that he dictates on an iPad. The process is very precise, almost as though Nicholas has become a master sculptor, reviewing the sweeping lines of a partially-finished stt, and lasts only a brief 10 minutes before the customer is seen to the door.

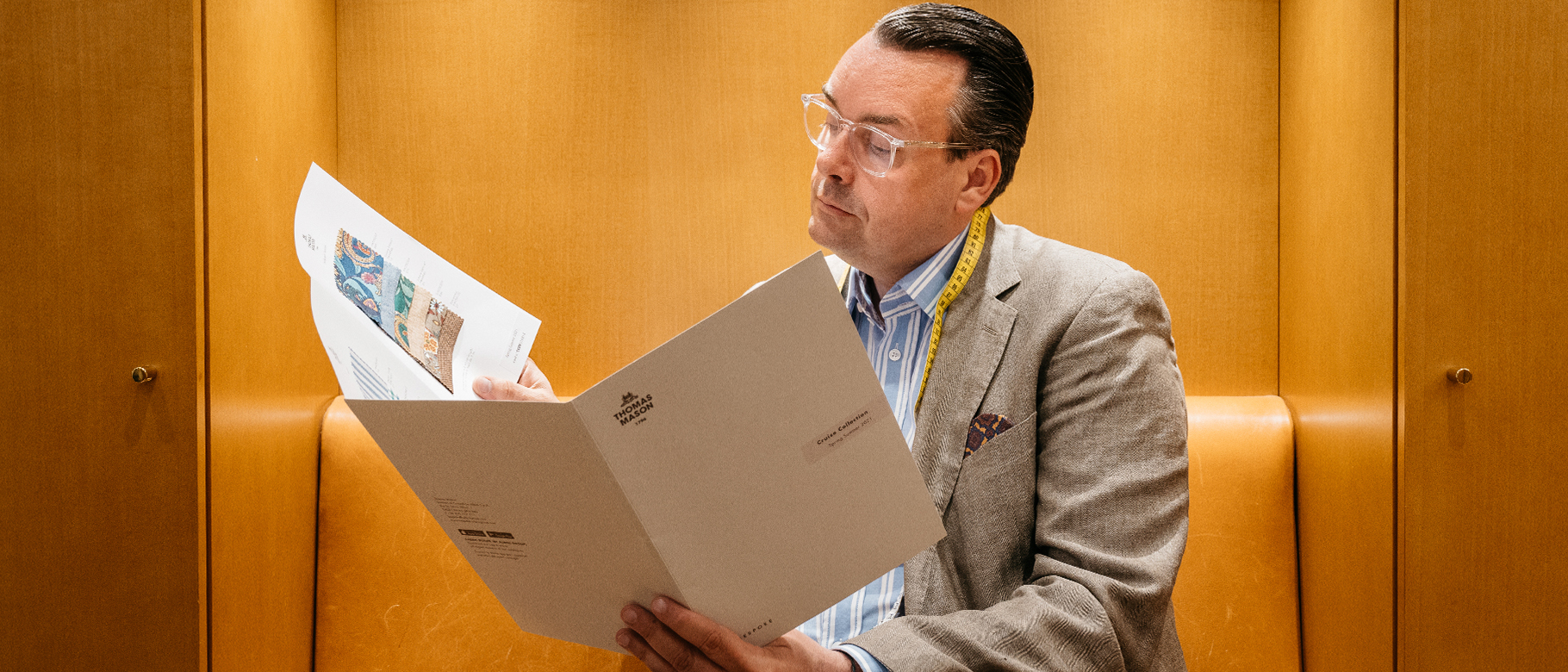

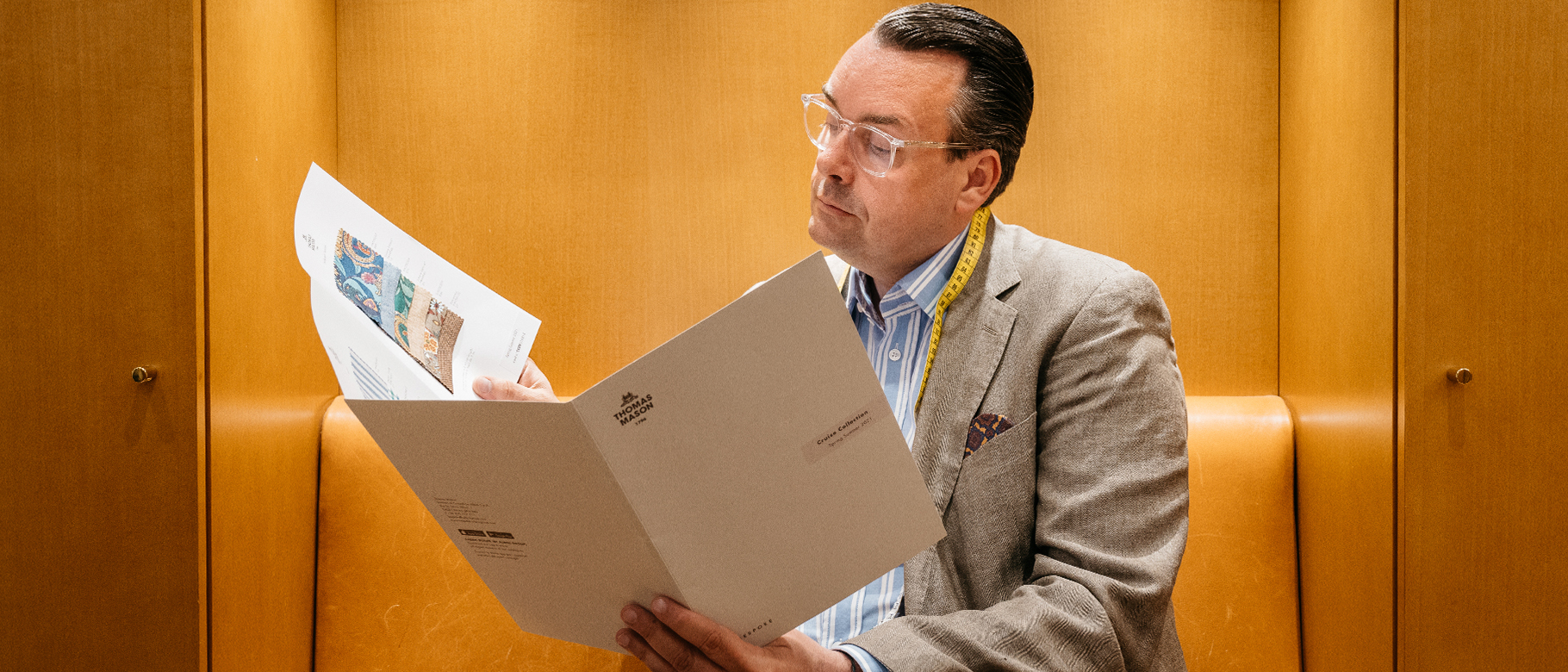

At this point, our conversation turns to Thomas Mason. “Today, Thomas Mason is our most important supplier,” Nicolas says pulling out some sample books from under the counter. “One reason for our slow and steady growth has been the ‘bespoke pronto’ programme offered by Thomas Mason. We have stock of more than 500 of their fabrics here – Silver Line and Gold Line from the Pronto programme are our bread and butter business. I also like the way that Thomas Mason dares to go new ways; to focus on sustainability and organic cottons for example, long before others jumped on this train. I think it is important that as few chemical substances as possible are used in the finishing process. We wear our shirts next to the skin, after all.”

Venturini shirts are delivered with spare fabric for new collars and cuffs and with a pocket handkerchief made of the shirting that was used – a thoughtful, personal touch. Stripes and checks are meticulously matched between yoke and sleeves and at the sleeveheads too. The sleeves are always set in by hand, while the shoulder and the side-seams are machined unless a customer specifically requests hand-finishing. The buttons are available in different shapes and sizes, the trademark house button is thin and slightly concave. The collars usually fused, but Venturini offers other options too: “We also make unfused collars and a mix of un-fused and fused,” Nicolas explains. “The latter option means that the neckband of the shirt is unfused and the top-collar is fused to make ironing easier.”

Two seamstresses specialise in hand-stitching initials. The selection of collars is impressive, customers can choose from 157 different models including seven different stand-up collars. “A lot of shapes have come together in the past decades,” says Nicolas with a modest smile. “The neckband is always bespoke. If a customer wants his personal collar copied, we will do that of course and the shape of the neckband will be made to the customer’s requirements.” When the ball season starts customers come in to have their white tie shirts starched. This is a complicated and somewhat messy procedure but the Venturinis are happy to offer the service: “In Vienna the ball at the Opera is a major event, we want our customers to look their best.” Unsurprisingly, orders for dress shirts to wear with tails should be placed well in advance.

While Nicolas starts to rifle through drawers filled with exquisite evening shirts to show me some of his signature creations, his daughter Valentina arrives. She has been helping out in the business for some months now when her studies permit. Nicolas likes to hear her opinion because her generation has a different view of fashion in general and of shirts in particular: “In my generation a shirt is usually something you put on to mark an occasion. It is rarely everyday wear,” she says, “I like shirts of course but I often wear sportswear too.”

Like all precocious youngsters, she has many ideas for the business and one of them is expansion: “I think we should open a shop in Salzburg. And maybe also in Germany, in Hamburg or in Munich.” She would run the new shop of course, “our customers expect to see someone from the family,” she says with a smile.

Learn more about Venturini at hemdenmacher_venturini

(Photos by Gregor Hofbauer)

The American Dream: Frank & Eileen

True Colours: Sartoria Margutti

Mond of Copenhagen talk 3D Body Scanning

Renaissance Man: Simone Abbarchi

Cotonificio Albini S.p.A. - Via Dr. Silvio Albini 1, 24021 Albino (BG) – Italy

Società con unico socio - diretta e coordinata da Albini Group S.p.A.

P.I. 01884530161 - C.F. 08743540158 - Iscritta al Registro Imprese di Bergamo - REA 244649

Capitale sociale sottoscritto e versato € 11.170.960