Cards on the table: the retrograde Englishman in me has always been fiercely opposed to the idea of making bespoke clothes using 3D scanning technology and the like.

The reason for that, of course, is that I come at bespoke tailoring from the viewpoint of a Savile Row snob, with preconceived ideas about what a ‘bespoke’ garment is. When brothers, Martin and Michael Birch Jacobsen decided – almost on a whim – to get into custom tailoring in 2011, they came to the market with no such preconceptions.

“Basically, we came into this business without any prior knowledge,” explains Martin, as we sit and chat over Zoom. He’s in the back office at Mond’s HQ in Copenhagen, in the company of Kevin Tournaux, the brand’s head of product development, and Natalie Dindorp, who is Mond’s chief marketing officer. The three make for an intriguing trio, each impeccably dressed in Mond’s signature softly-constructed tailoring and crisp, contemporary shirts. “Our naivety was both a blessing and a curse because we did things very differently to many of the established brands in our space,” Martin continues.

“Early on, we made a lot of mistakes with our production, but eventually we got it right and the business took off.”

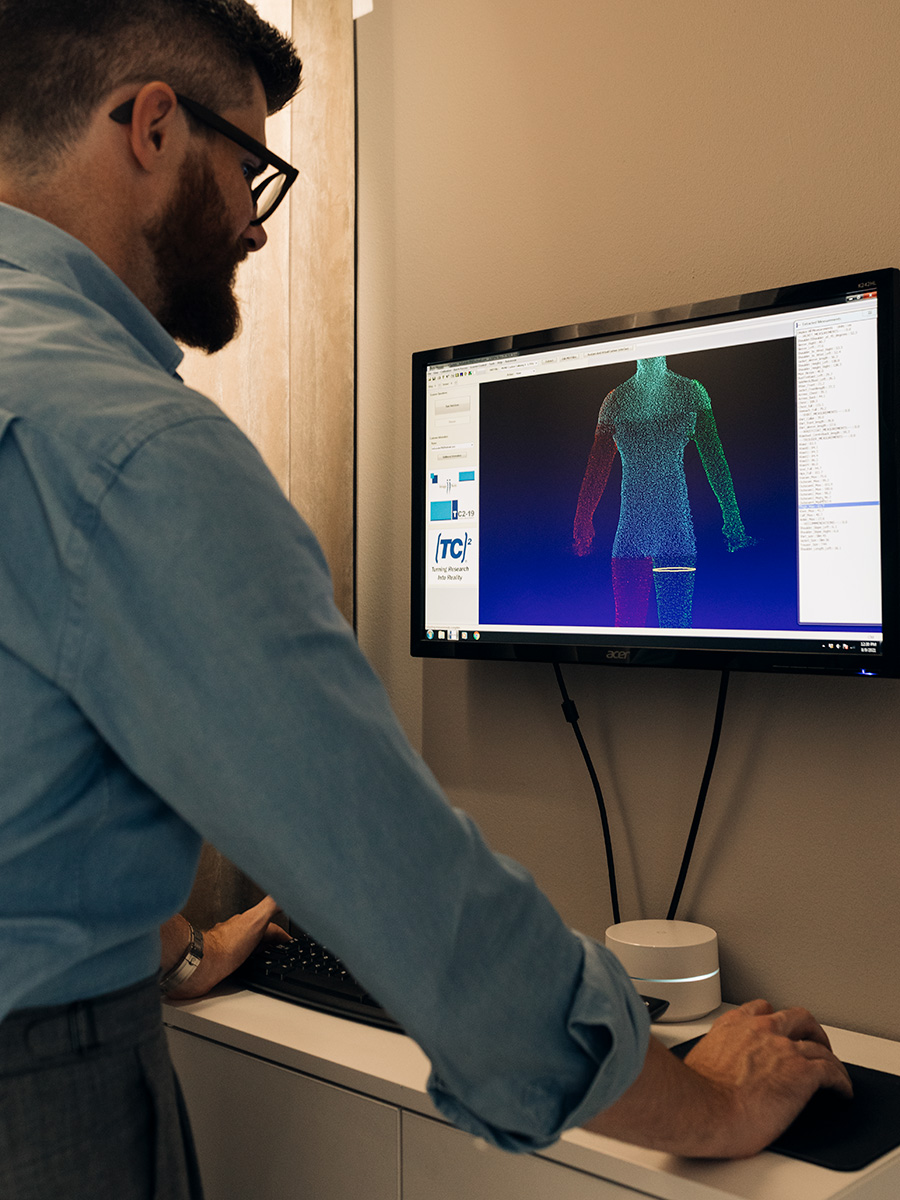

Mond’s distinguishing feature, you’ll probably have guessed, is that the brand makes both competitively priced made-to-measure suits and shirts using 3D body-scanning technology. But, unlike a number of brands who’ve tried this over the years with limited success, Mond seems to have cracked the code. In recent years, the business has grown swiftly with four shops across Denmark, and an international reputation for quality. Keen to explain the benefits of body scanning, Tournaux talks me through the process for a first-time customer.

“It’s very similar to typical bespoke,” he says. “The client comes in, we have a discussion about the garment and what they’re looking to achieve, before we spend some time choosing cloths and details. Then, the scanner will take your main measurements like your chest, stomach, hip, biceps and so on, but we’ve also coded the scanner to draw on all the data we hold on past clients’ configurations too. This allows the scanner to refine both your base size and alterations for extra accuracy. When we scan a new guy, the system will look at all of our past clients – it’s constantly learning and refining how to fit our customers.”

It sounds thoroughly impressive, and Natalie, ever the marketeer, helps to reinforce this impression: “It’s interesting to hear that in the UK there’s a lot of resistance to body scanning technology,” she says, as we chat. “We have the opposite issue in Denmark – guys find the idea really interesting, but sometimes are concerned it’s just a marketing scheme. We’ve spent a lot of time and energy communicating that we use the scanner to enhance what we can do, but it’s important to note that we don’t depend on it entirely, like other brands do.”

Kevin helps to explain that what sets Mond apart is the fact that scanner and tailor work together with the client, to ensure that personal preference and the human touch also have a bearing on the finished garment. “Basically, the scanner gives useful recommendations that we can then discuss with the customer,” he says. “Let’s say you’re 70 per cent a size 41 and 30 per cent a size 42 in terms of your ‘base size’. We can then share this information with you and explore your personal preferences. If you’d like the garment to be a little bit more roomy, we’ll choose to go with a 42, and then subtly bring some elements of the size 41 into your pattern where the scanner tells us this makes sense.” Clever stuff indeed.

What about Mond’s shirts, then? The brand doesn’t have a particular house style, but instead offers customers a wide range of customisation options, from collars to cuffs, using the same body-scanning technology that goes into its custom tailoring. The result is a clean, sharp-looking shirt with a flawless fit. “For us, it’s about trying to bring in as many of the perks to bespoke shirtmaking as possible, while also keeping to a reasonable price point,” explains Tournaux.

Of course, with quality in mind, an obsession with fabrics runs throughout Mond’s offering – and shirting is no exception. “We’ve always been grateful to Thomas Mason,” Tournaux continues, “they agreed to supply us when we were brand new, and they really took a risk on us. Today, their range is so extensive that every time I need to develop a new fabric or find something new, they’re my first go-to.” So much so, that Mond is actually working with Thomas Mason to create the perfect off-white cotton shirting for Mond’s wedding customers – building on the popularity of Thomas Mason’s white Journey shirting, which, according to Dindorp, is the “all time top-selling shirt” at Mond.

“Finding the perfect off-white shirt is difficult, but it can be so much more elegant than bright white,” says Birch Jacobsen, “Thomas Mason are trying to perfect this for us at the moment – weaving an off-white satin with a lovely sheen that doesn’t crease too much during the day. It’s been a long process, but I think we’ve got it now. The last sample was spot on.”

Evidently, a spirit of innovation and a will to contemporise classic menswear sets Mond apart. I entered our conversation a 3D scanning skeptic, but I left wishing I could hop on a plane to Copenhagen and try it.

Visti Mond website and buy here.

Photography by Milad Abedi

Renaissance Man: Simone Abbarchi

Northern Soul: Dooley & Rostron

In Personam: Good Counsel

Cotonificio Albini S.p.A. - Via Dr. Silvio Albini 1, 24021 Albino (BG) – Italy

Società con unico socio - diretta e coordinata da Albini Group S.p.A.

P.I. 01884530161 - C.F. 08743540158 - Iscritta al Registro Imprese di Bergamo - REA 244649

Capitale sociale sottoscritto e versato € 11.170.960