Nicolò Lacalendola is his family’s third generation to have made menswear his life. The tradition dates back to 1971 when his grandmother Agnese Turri began working out of the basement, hand-making shirts from her home in Jerago con Orago, not far from Lake Como in northern Italy.

This homespun operation continued to expand and, under the guidance of Nicolo’s mother, Luisa, the family began a long list of collaborations with leading designer brands – including Dolce & Gabbana, Balenciaga and Missoni to name just a few. These were so successful, the family decided to open a workshop in the early ‘90s, and began by making a few items for friends and family. The shirts were an instant success, demand grew exponentially and Camiceria Turri was born.

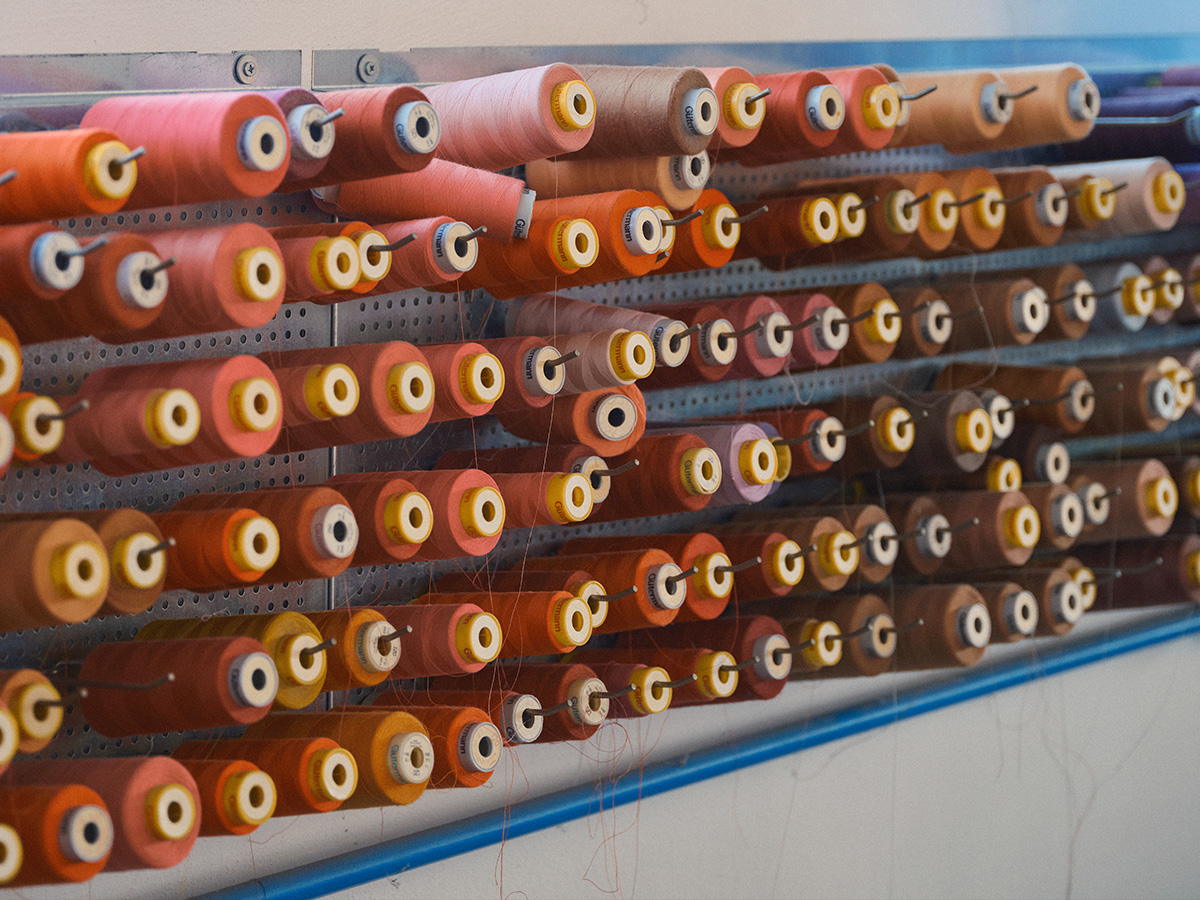

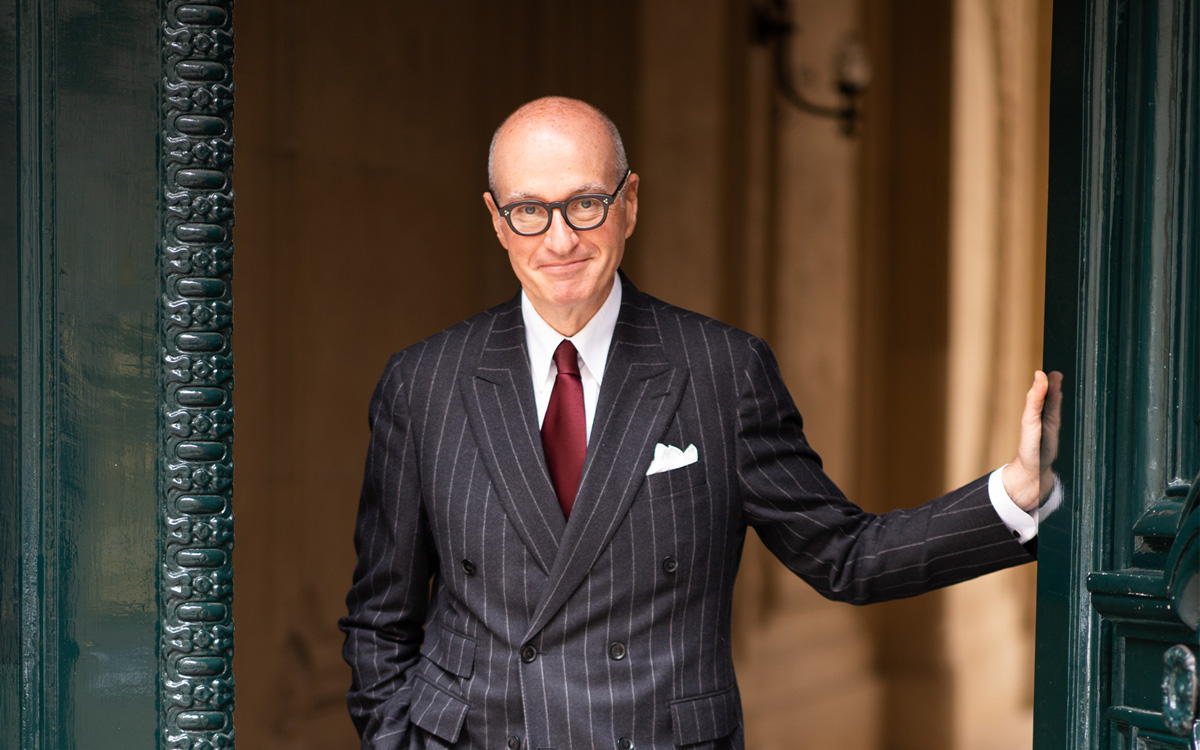

“I was raised in the Camiceria,” says Nicolò, “the smell of new fabrics and the rhythmic metal sound of the sewing machines are in my blood. I could never live without it.” Now in his 30s, Nicolò works alongside his father to meet their loyal clientele’s exacting requirements.

“It’s essential to understand what clients want and allow for the experience in our laboratory to be a special moment for them,” Nicolò adds. The ‘laboratory’ is Turri’s nickname for the shirtmaking atelier – and speaks to the team’s willingness to experiment. “First, we sit down with a coffee for a chat, and we look at possible styles and fabrics,” he adds. Once the shirt has been designed in close consultation, an initial test shirt is cut and sewn together to fit on the client. Turri then use this shirt to perfect the client’s pattern and hone the fit of all future shirts to perfection.

Home visits are available to take measurements and make the process as easy as possible for busy customers. “Pre-pandemic, we used to offer this service in various countries. I would travel to London, Paris, Monaco,” explains Nicolò. “Now, we are looking at the market in Dubai as a possible next step. This without taking away any of the time and care we dedicate to our local clients, of course.”

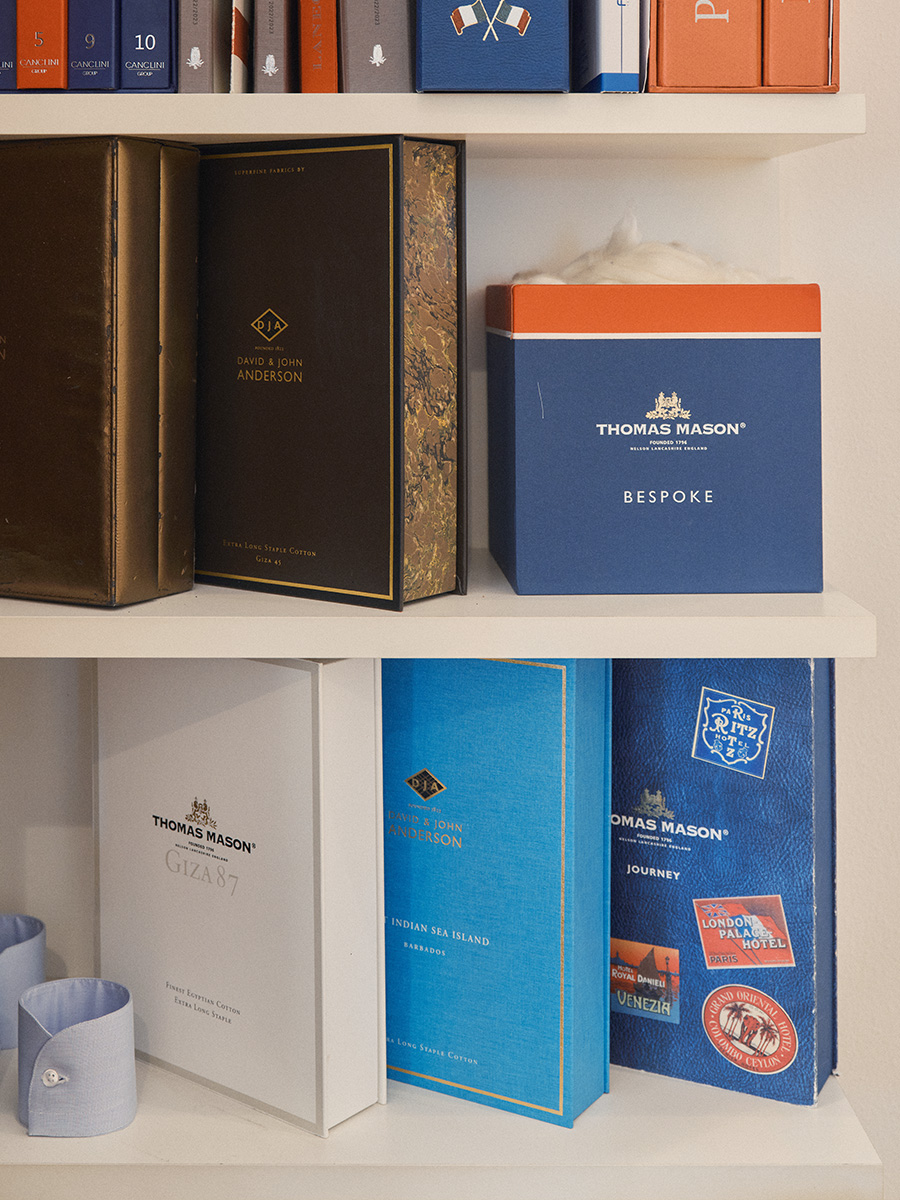

A close, personal relationship with clients is paramount at Turri, and helps to ensure a consistently high quality of both service and products. For the team, the need to uphold the excellence of artisan products and the reputation of ‘made in Italy’ starts from sourcing the best materials. “When selecting the fabrics, we look for Italian products,” confirms Nicolò, “from the buttons to the interlinings, we want to keep the flavour of Italian craftsmanship throughout.”

The brand began with classic shirts in traditional colours, but quickly expanded to optimistic, multicoloured fabrics and more modern designs. The summer 2022 season saw the introduction of bowling shirts and shorts, while oversized shirts in velvet or Thomas Mason’s superior Balmoral cottons are some of the most requested items year-round.

As you’d expect of a fine Italian shirtmaker, seasonal edits of cloths are regularly selected and updated, from Oxfords and poplins, to flannel, linen and silk. While the arrival of wrinkle-resistant cottons – most notably from Thomas Mason, of course – was a marked success with clients.

When asked about the perfect shirt, Nicolò doesn’t hesitate, and specifies a white double-twisted twill shirt, preferably with a 140s yarn count to keep it fresh. “A white shirt is like a pizza Margherita,” he says. “You can never go wrong with it, and it suits all occasions.”

It’s even better if it’s cut with the brand’s signature Turri collar, the result of a production error encountered while the workshop was trying to solve the sinking that can sometimes happen in the back of a soft shirt collar. The result is a rigid collar that holds its shape beautifully, similar to the classic button-down but without buttons to restrain the collar roll – it works perfectly with a tie when fastened.

Whether by accident or a willingness to innovate, new product ideas are welcomed by Turri’s father and son duo. Once a prototype is created, it is the client’s feedback that decided whether the new item will make it into further production or not. If successful, the brand’s makers get to work and before too long a new type of shirt hits the shelves.

With the family’s legacy on his shoulders, Nicolò looks at the future with both anxiety and excitement. “My main concern is the generational change that will need to happen in the laboratory,” he says. “It will be a big problem not only for us, but for craftsmanship on a national level. Sadly, the new generations in Italy don’t seem to recognise this as a potentially fulfilling career.”

Nevertheless, the camiceria has proactively prepared for this next step and brought on apprentices willing to learn the necessary skills. The team includes three young girls from Iran, Romania and China, who joined the house this summer. “Our laboratory will be multilingual soon,” says Nicolò, smiling.

When asked how he envisions the future of Turri, his voice fills with enthusiasm. “I would love to expand further and let our product be known in new markets. But most of all, we will have to focus on reducing our impact on the environment, and at a local level. This is going to be one of the upcoming challenges for us and the industry at large.”

Explore Camiceria Turri at camiceriaturri.it

Photography by Andrea Puggiotto

Polite societé: Daniel Lévy

Crane Brothers: Antipodean Dolce Vita

Ascot Chang: A Legacy of Quality

Cotonificio Albini S.p.A. - Via Dr. Silvio Albini 1, 24021 Albino (BG) – Italy

Società con unico socio - diretta e coordinata da Albini Group S.p.A.

P.I. 01884530161 - C.F. 08743540158 - Iscritta al Registro Imprese di Bergamo - REA 244649

Capitale sociale sottoscritto e versato € 11.170.960