In the late 19th Century, mutton-chopped British and American entrepreneurs were making a mint trading opium, tea, spices, silk and other exotic commodities in and out of China. These prosperous businessmen sought to flaunt their new wealth – and what better way to do so than through sartorial finery?

London tailors scented enough potential profit that they were willing to brave an arduous four-month sea journey eastward to cater to this newly affluent clientele. Upon arriving in China, the canny expat tailors hired and taught local assistants the intricacies of western-style garment cutting and construction. As the Chinese apprentices became masters, many left their foreign employers to establish businesses independently.

By the 1920s, Shanghai had developed a highly sophisticated sartorial scene and a style all its own, drawing upon British, continental and – after an influx of talent following the Bolshevik revolution of 1917 – Russian tailoring. It was in this setting that the young Ascot Chang cut his teeth as a tailor.

“My father came to Shanghai from rural China in the 1930s,” explains Tony Chang, offspring of the eponymous founder, who today runs the business with his own son, Justin. “At that time, the tailoring techniques in Shanghai were very mature, up to the standard of the London or Paris. That’s where my father learned the art of shirtmaking.”

After World War II, civil conflict broke out in China, leading into the Communist Revolution of 1949. “The economy was in chaos,” Tony explains, “but my father was newly married with his first child, and he needed to support his family. So he travelled to Hong Kong alone and lived with an uncle, also a tailor from Shanghai. That’s when he started his shirtmaking business, going office to office visiting customers, some of whom were tycoons he knew from Shanghai.”

By 1953, Ascot had accumulated enough wherewithal to open his own store, on Kimberley Road in Tsim Sha Tsui, Kowloon, on the Hong Kong mainland. “The tailoring business was booming in those days,” Tony says, “and on Kimberley Road, there were many tailors – but my father was the only one who did shirts. So the other tailors would refer people who wanted shirts to my father.” Business was sufficiently brisk that a decade later, Ascot was able to establish a retail presence at the plush Peninsula Hotel.

Tony says his father won a loyal clientele who appreciated the “very English way” Ascot Chang made shirts, while charging prices substantially below those levied on Jermyn Street in the 1960s and ’70s. “In those days, when I first joined the business, our reputation was built on making excellent quality shirts for a very reasonable price,” he explains.

Ascot had pioneered offering his services at trunk shows in the United States, flying in to measure up clients and shipping their shirts back from Hong Kong. “When we’d visit New York, the gentlemen from Wall Street would come in and order six or 10 shirts in matter of a few minutes, because one of our custom shirts cost less than ready-to-wear from a department store,” Tony recalls.

That is no longer the case, and today, while Tony says Ascot Chang’s prices remain competitive, their key selling point is their quality. “Nowadays I would say our customers come because they trust in our name, they trust in the quality of the construction and fit,” he says. “We have very demanding customers, and we are able to satisfy a very demanding customer – that’s how we built this business.”

Justin Chang says it’s very important to him and his father that the attention to detail Ascot Chang founded his reputation upon is maintained. “It’s a big responsibility, for sure, to keep those quality levels constant, especially in terms of how we make the shirt,” Justin says. “We must have 21 stitches per inch. We must have French seams. We must take a great deal of care to do the cutting so that the stripes or the checks match as perfectly possible. These are all hallmarks of a high-quality bespoke shirt.”

In carrying on his grandfather’s legacy and living up to his name, Justin says, “We need to make sure that we’re safeguarding those standards. And then actually, in some ways, we need to be improving on certain things. For example, in terms of fitting, you’re always learning something new. Body shapes have changed a lot over the last 50 years in parallel with people’s habits. Now, people are going to the gym a lot more, physiques are evolving and we need to evolve with that.”

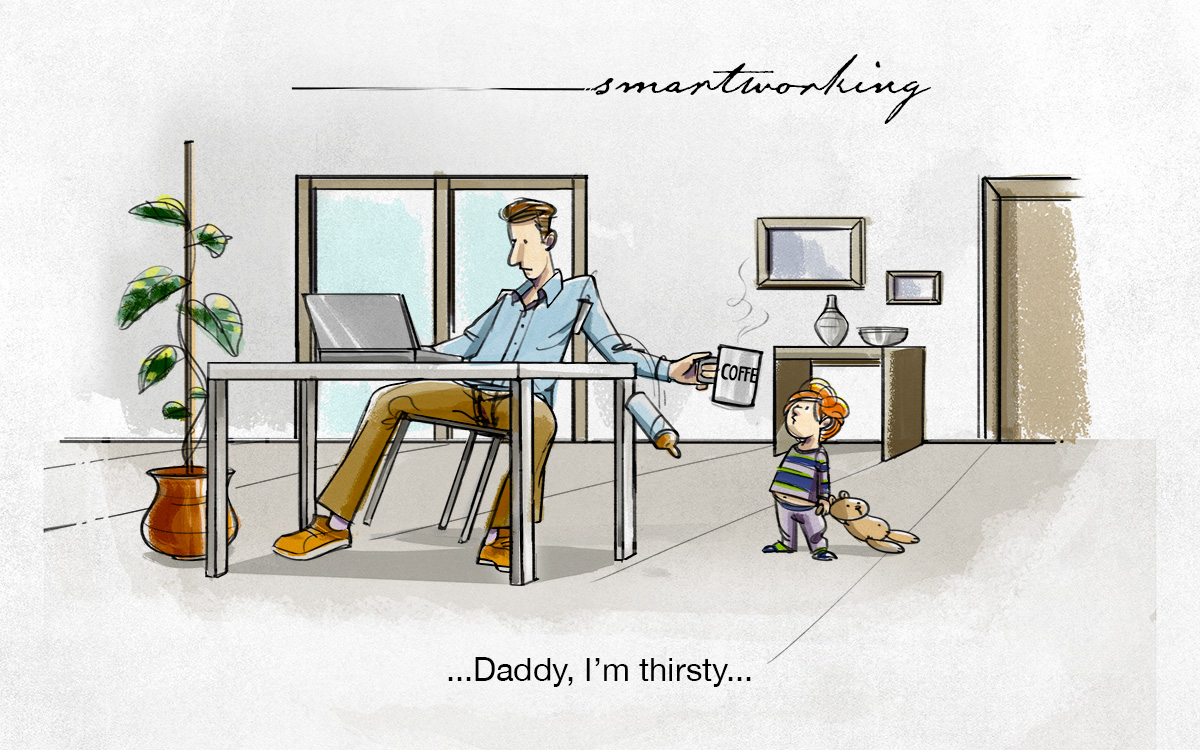

A shirtmaker has to move with the times, which today means making more shirts that can be worn tie-less and exploring new modes of dressing. “Since our collaboration with the Armoury guys, eight or nine years ago, hybrid garments like shirt-jackets and more casual tailoring have been growing steadily for us every year,” Justin says, “and that’s only accelerated since COVID hit, with work from home and everything.”

Nevertheless, as much as things change, you still can’t go past a classic white shirt, Justin reckons. “Those core white cloths, the poplins and thin twills that don’t have too much of a sheen, those are always the core of what we do,” he says.

In that area, Justin explains, “Two of our best sellers are Thomas Mason Silverline cloths, because of how hard-wearing they are and how well they last. Customers say they keep washing and washing the shirt and it just gets softer and softer. That’s why they keep going back to those cloths, they refuse to go to anything else.”

Tony says as customers come to appreciate the difference a quality cloth can make, they naturally begin to upgrade. “Once we have the fitting right, a customer might move from Thomas Mason 100s to try a shirt in Silver- or Goldline. Once a customer gets into that arena and tries those superior fabrics, they will come back for it. We don’t need to encourage them,” he says.

“I know from personal experience, you can feel the difference. When I first tried the Thomas Mason Goldline 140s, it was so nice, so soft and silky and yet has body to it,” Tony rhapsodises. “Once you’ve tried a cloth like that, there’s no going back.”

Photo credits: Tory Ho

All hail ‘The Leopard’

Henry Poole: The Benchmark for Tailored Tradition

Take a tour through Alan See’s Hong Kong

Shirts for Sophisticated Home-Working

Cotonificio Albini S.p.A. - Via Dr. Silvio Albini 1, 24021 Albino (BG) – Italy

Società con unico socio - diretta e coordinata da Albini Group S.p.A.

P.I. 01884530161 - C.F. 08743540158 - Iscritta al Registro Imprese di Bergamo - REA 244649

Capitale sociale sottoscritto e versato € 11.170.960