Bespoke shirts reflect the aesthetic sense of the people who craft them.

If aesthetic sense is truly a byproduct of culture, then British shirts have a solemn dignity, Italian shirts are soft yet flamboyant, and French shirts are imbued with refined elegance. Japanese shirts, however, have a clean-cut beauty sustained by precision–the result of scrupulous attention to detail that is uniquely Japanese. The shirts made by Yuta Minami of MINAMI SHIRTS are prime examples.

After graduating from a school of fashion arts in Tokyo, Minami joined a shirt factory in his hometown of Noda City, Chiba. Although he was entirely focused on machine sewn shirts at the time, the experience opened his eyes to the joys of shirtmaking. He taught himself bespoke shirtmaking while working at the factory and established MINAMI SHIRTS thereafter. With no theories derived from his experiences about the proper way to make shirts, Minami produces bespoke shirts with his original method.

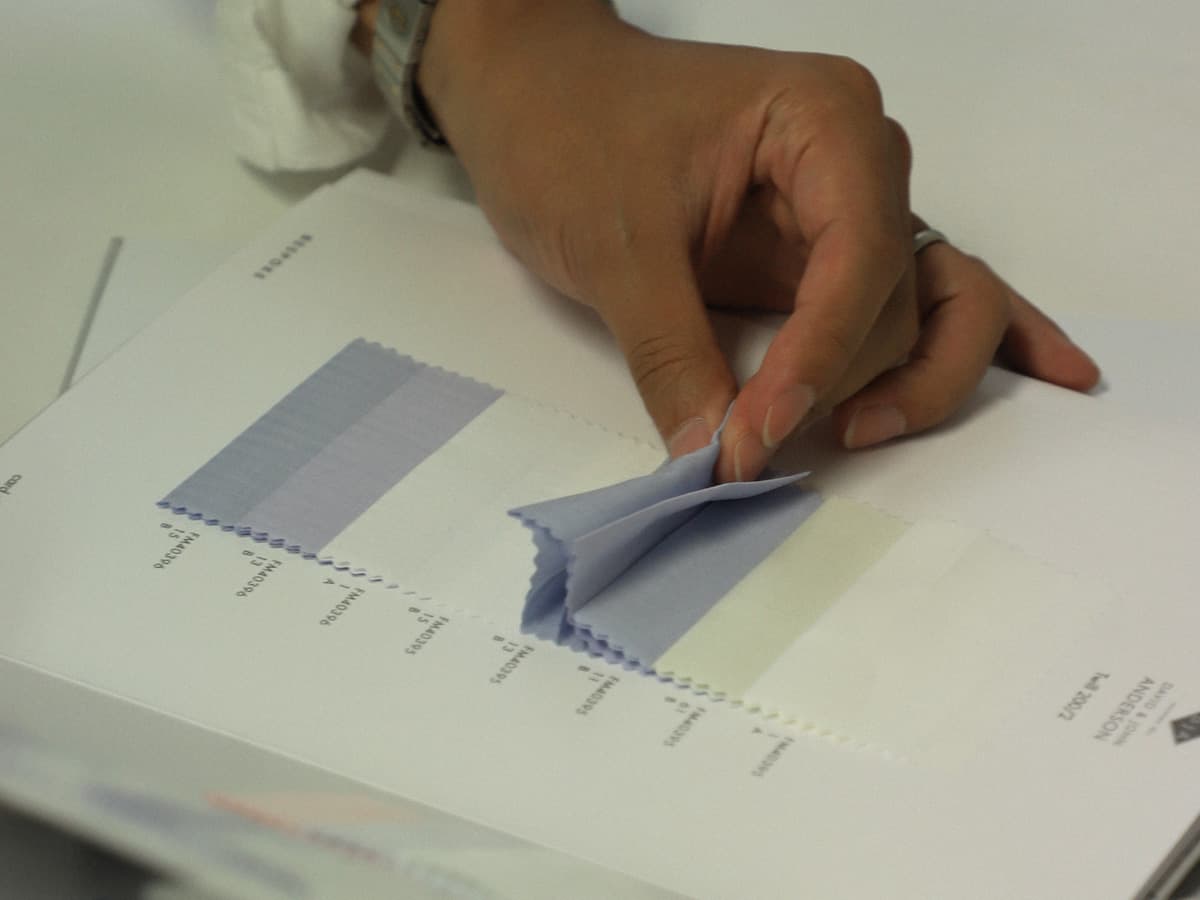

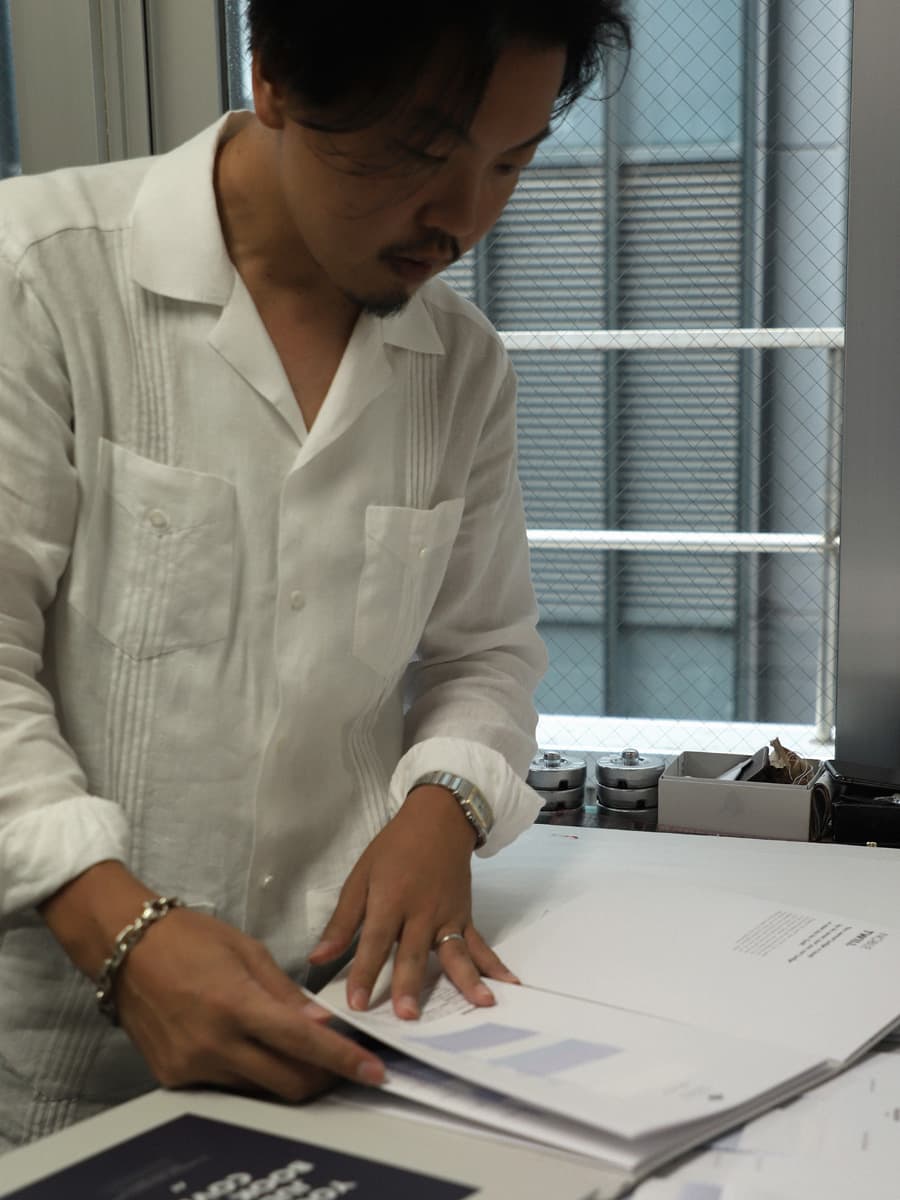

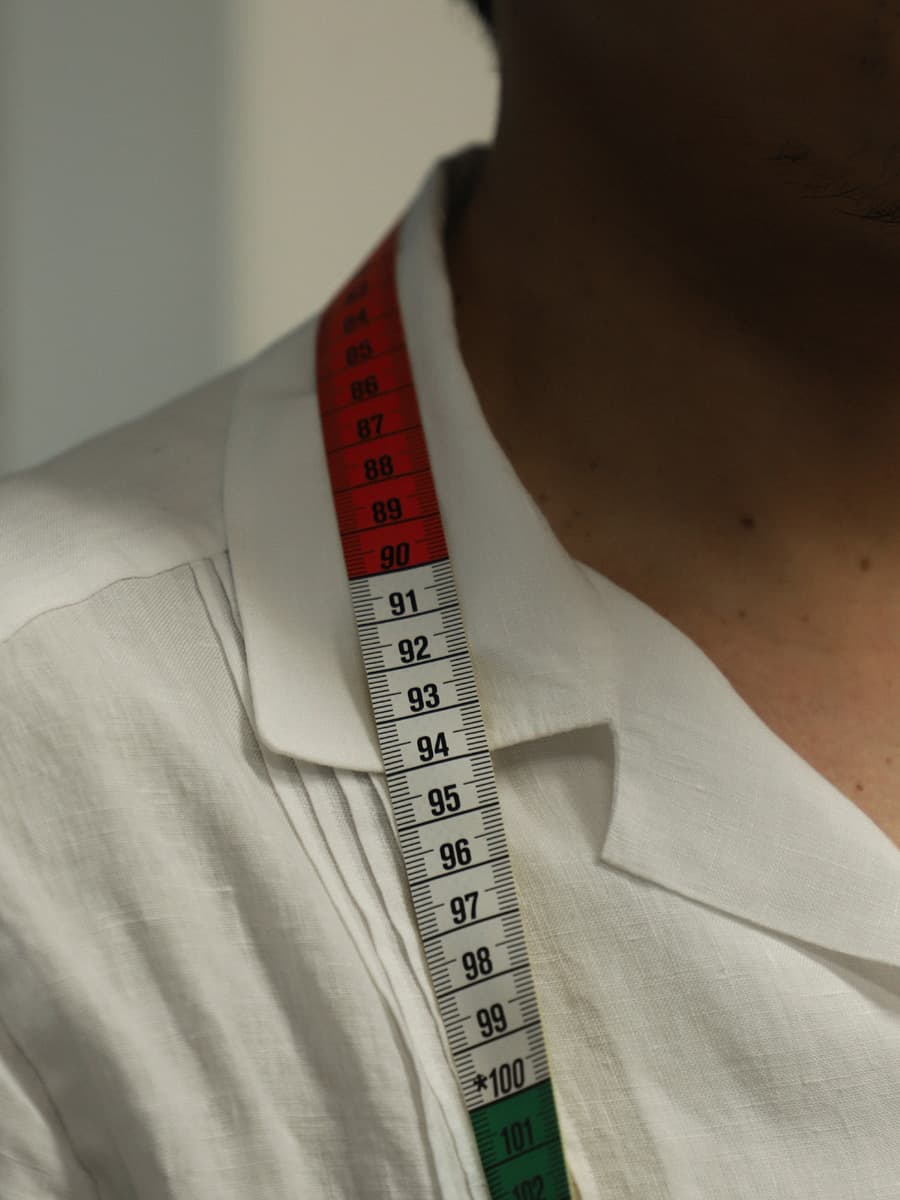

When face to face with a client, Minami first considers how to replicate the client’s physique using a length of fabric; he then drafts the pattern. There is no basting after measurements have been taken. For first-time clients, Minami enquires into everything from how and where the shirt will be worn to how it will be laundered. Twelve fundamental measurements are taken, along with photographs and an additional eight measurements to capture the client’s standard posture and other subtleties. Compiling measurements and personal data enables Minami to make precisely the shirt that the client really needs.

MINAMI SHIRTS have no characteristic style. In reality, it is the technical prowess that enables the company to fulfill every client’s requests that MINAMI SHIRTS is considered the ideal bespoke shirt manufacturer.

MINAMI SHIRTS has two lines: made to measure (MTM), which is sold at Mitsukoshi Isetan Department Store, and the bespoke line, which Minami handles personally. With the bespoke line, the client can request any option, including collar style, cuffs, placket shape, fabric and places to be sewn by hand. If the client requests it, everything can be given a hand sewn finish, from front and back shoulder seams and armholes to blind hems and bartacks.

Minami also applies an ingenious twist to MTM patterns, which are difficult to tweak. Slightly lowering the point at which the collar overlaps below the neck so that it falls below the Adam’s apple makes neckties comfortable to wear when they are tightened, rather than constricting. Lowering this point also works to make the neck appear longer.

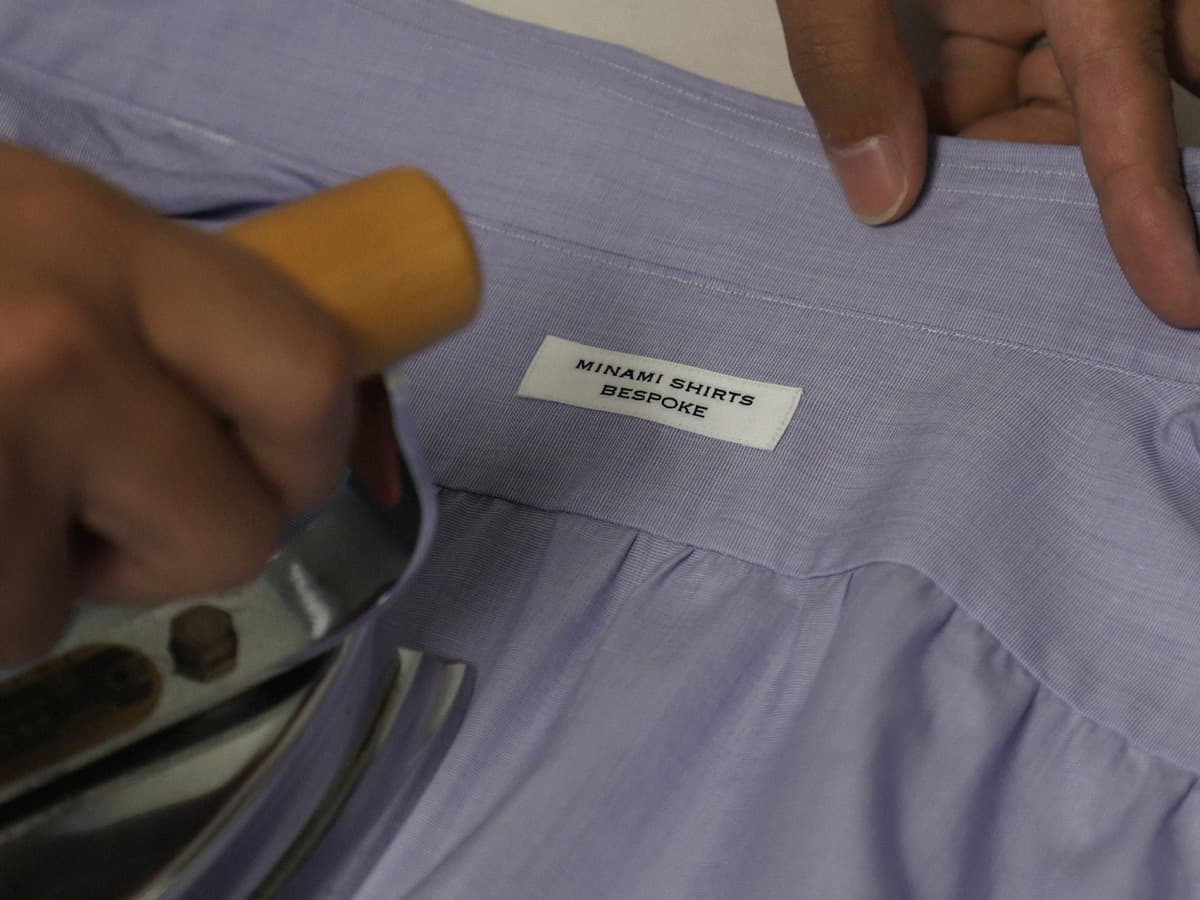

Whether or not hand sewing is superior is always a point of debate in shirtmaking. According to Minami, there is no difference in comfort between hand sewing and machine sewing. Unlike suits, shirts are washed and ironed after one wearing. With hand sewing, ironing easily puts pressure on the thread and the stitches sometimes catch. Although broken thread can be fixed, torn fabric means fatal damage. Being intent on clients enjoying getting the utmost wear out of their shirts, Minami believes that machine sewing is more practical in terms of strength.

Buttons, however, are the element of MINAMI SHIRTS for which hand sewing is a constant. Buttons attached by hand are uniformly spaced and leave a slight gap, allowing shirts to button up easily. Minami orders special buttons from a manufacturer in Nara Prefecture; recessed in the center and with raised edges, they can be managed easily. Buttons are available in 1mm increments, with 3.5mm being the standard thickness. Different sizes, such as 2.2.mm, have different uses, depending on the fabric. By Minami’s request, the buttons he orders have “Made in Nara” printed on the back to show his support for the producers in Nara Prefecture, who are responsible for 80% of Japan’s shell-button manufacturing.

For collar style, which determines the impression a shirt make, Minami consistently pursues the beauty of a clean line. Clients can specify details that not only include shape but also the point up to which stitches are placed. Minami’s wide spread collar is popular. Practicality is emphasized here as well: the patterns shape the collars for easy ironing and also dry cleaning. Interlining used for cuffs and collars is usually die cut all at once at factories, but MINAMI SHIRTS cuts each piece on the bias instead. This allows the original dimensions to be restored when a shirt is washed and then stretched during ironing. Although this method is expensive and time-consuming, it improves feelings of fit and comfort, with no shrinkage. This type of ingenuity -not visible on the surface- makes MINAMI SHIRTS comfortable to wear.

What Minami thinks is technically difficult is securing a range of motion that adjusts by gathering the fabric from the sleeves to the back and establishing the image of the collar. While many shirt manufacturers take in the waist where it is the thinnest, Minami makes it a point to adjust it to where the belt should be worn so that when the wearer bends down, the shirt stays tucked.

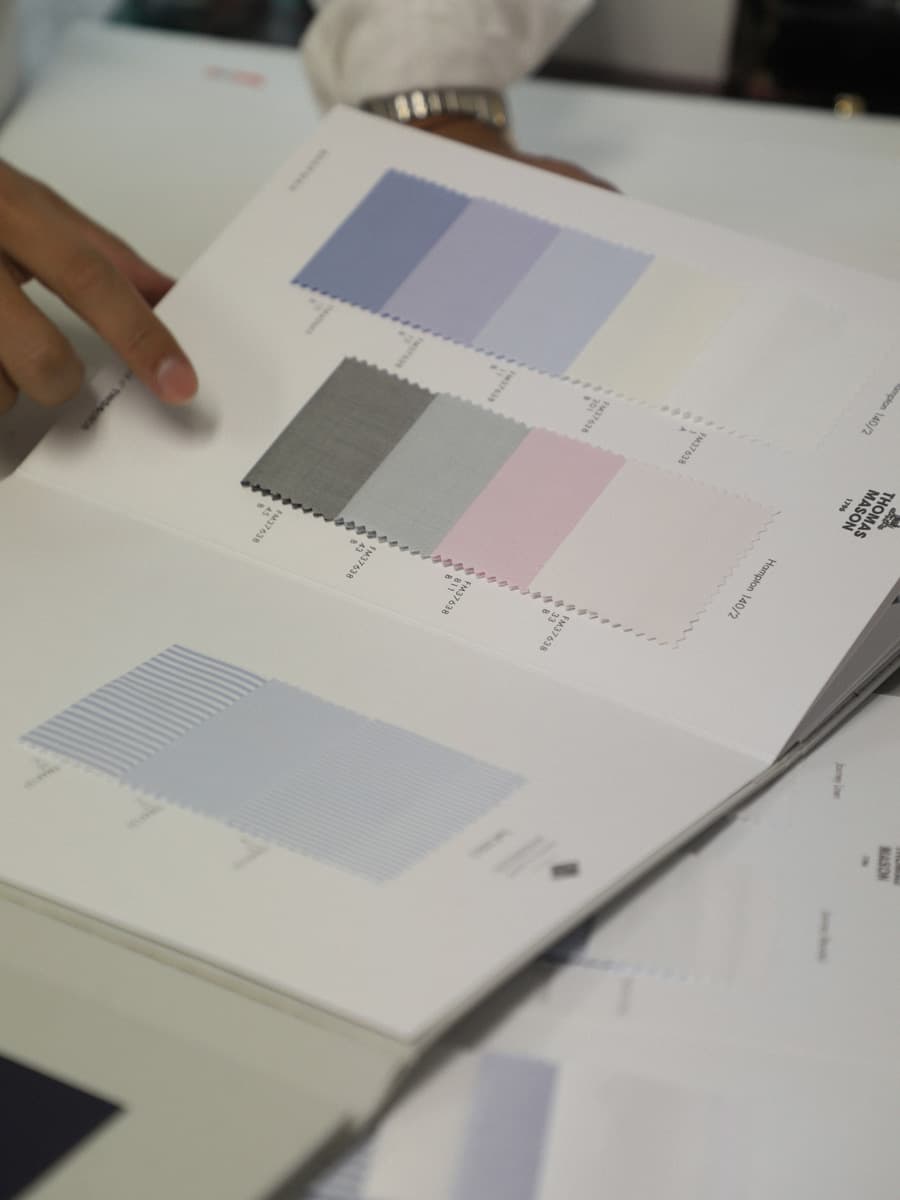

In Japan, the business demand for bespoke shirts is high, and reliability is key. Japan’s history with Western clothing began with Savile Row. In light of this, Thomas Mason, an establishment of long standing in the UK, is a name of proven reliability and quality for Japanese people. Particularly recommended is the highly reliable Thomas Mason 140 2-ply: appropriate for every business scenario and hard to wrinkle (even in Japan’s hot and humid climate), it also has a beautiful, understated luster.

Meeting the client’s every demand: this is what Japan’s bespoke shirtmakers take pride in. Japan’s history with Western clothing began in 1872 with the Meiji Emperor and the Daijokan Fukoku (a decree issued by the Grand Council of State). Now, roughly 150 years later, Japan’s craftsmanship has earned an excellent reputation overseas as well. This craftsmanship is said to be characterized by precision and perfectionism, but that is not all: it demands devotion to clients and unstinting efforts so that they are truly fond of their shirts. This is the essence of craftsmanship in Japan. This is the philosophy that molded MINAMI SHIRTS.

(Photography by Yuthanan Chalmeau)

Why we think you should be an Anthologist

Swann Custom Shirts, a Shirtmaker Built For Today

Budd Shirtmakers – Making The Case For Tradition

Cotonificio Albini S.p.A. - Via Dr. Silvio Albini 1, 24021 Albino (BG) – Italy

Società con unico socio - diretta e coordinata da Albini Group S.p.A.

P.I. 01884530161 - C.F. 08743540158 - Iscritta al Registro Imprese di Bergamo - REA 244649

Capitale sociale sottoscritto e versato € 11.170.960